Products

Equipment

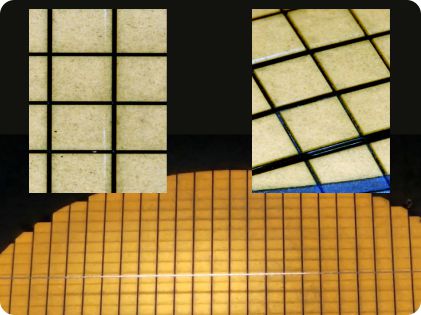

Specially developed for cutting 4 to 8 inch wafers of brittle and hard materials such asWide Band Gap Semiconductors and ceramics, this equipment provides excellent cutting edges and efficient grain cutting.

Specially developed for cutting 4 to 8 inch wafers of brittle and hard materials such asWide Band Gap Semiconductors and ceramics, this equipment provides excellent cutting edges and efficient grain cutting.

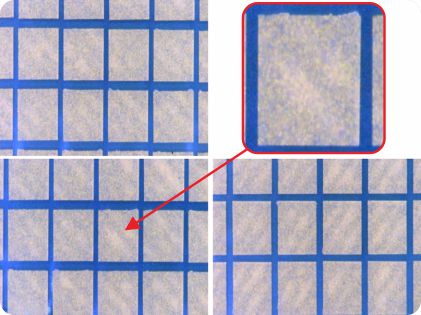

Dicing Saw Blade - Fluorescent Ceramic Blade

MDS-68A Blade - Fluorescent Ceramic Blade

• Single-edge diamond wire saw with reciprocating operation, controlled by microcomputer and PLC. • High-speed wire design paired with MDWEC diamond wire, reducing processing time by 50%, lowering costs, and boosting productivity. • Oscillation function can be set for superior control of finished thickness and surface quality. • Suitable for high-hardness, brittle materials; versatile worktable design allows for cutting a wide variety of workpiece shapes. • Low wire loss (kerf-off), minimizing subsequent processing time (lapping & polishing) and reducing labor, time, and material waste. • User-friendly interface ensures smooth system communication, easy operation, simple maintenance, long consumable lifespan, and easy access to replacement parts.

| Equipment | Model No. | MDS-68A Wafer Dicing Saws |

| Size | 1500mm(L)*1800mm(W)*1750mm(H) | |

| Weight | 2000kg (Approximately) | |

| Diamond Wire | Wire Speed | 2000 meter/min. (max.) |

| Wire Storage/Length | 8~20km (* Diameter various) | |

| Tension | 5~20N | |

| Diameter | 0.08~0.15mm | |

| Dicing Parameter | Cutting mode | Forward/Backward |

| Thickness of workpiece | 0.1mm (min.) ~ 10mm (max.) | |

| Size of workpiece | 1 ~ 203.2mm (8" wafer) | |

| CCD alignment accuracy | ±0.01mm | |

| Rotary accuracy | ±0.01mm | |

| Facility | Electric Power | 220V, 50/60HZ, Ф3Phase |

| CDA | 0.4-0.6Mpa | |

| Air consumption | 100Liter/min (Approximately) | |

| Coolant | Pure water/water usage is adjusted based on cutting quality. |